How to Keep Commercial Glass Doors Clear and Condensation-Free

For any commercial glass door refrigerator, clarity means everything. A transparent and fog-free door is the first thing a shopper notices — it invites attention, showcases your products clearly, and drives the desire to buy. However, when condensation builds up and the glass becomes foggy, the display effect is ruined. Customers can no longer see what’s inside, and the products lose their visual appeal. For supermarkets, convenience stores, and beverage brands, clear visibility is as important as good cooling performance.

At TCCOOL Refrigeration, we understand that visual presentation plays a major role in sales. That’s why our engineering team continuously improves the door glass design to minimize fogging and water condensation under different climates and temperature environments.

After years of testing, we typically apply one of the following three anti-condensation solutions depending on the customer’s usage scenario:

1. Low-E Glass (Low Emissivity Coating)

This is one of the most efficient and widely used technologies to prevent condensation on commercial coolers. Low-E glass features a special coating that reduces the heat exchange between indoor and outdoor environments. By minimizing the temperature difference on the glass surface, it effectively prevents fog formation.

The result: the door remains crystal clear, even in humid environments. Besides that, Low-E glass is lightweight and energy-efficient, which makes it ideal for upright coolers, beverage display cabinets, and supermarket showcases where energy saving and door balance are important.

When to choose:

- Ideal for beverage coolers, chillers, and open display units.

- Best balance between performance, appearance, and cost.

2. Triple-Layer Glass Door

Triple-layer (three-pane) glass doors offer higher insulation by adding one more air gap between the glass layers. The multiple layers help to slow down heat transfer and reduce surface condensation. This design is especially helpful in areas with very high humidity or strong temperature differences between inside and outside the cabinet.

However, there are trade-offs. The extra layer makes the glass heavier, which adds pressure on door hinges and may slightly increase the long-term maintenance frequency. For this reason, our R&D team carefully evaluates the door size, structure, and hinge strength when designing triple-layer doors.

When to choose:

- Recommended for large upright coolers or high-humidity regions.

- Excellent for long-term cold retention and minimal condensation.

3. Heated Glass (Electrical Heating Film or Wire)

Heated glass is another powerful solution to prevent condensation. It works by using a thin heating film or embedded wire system that gently warms the glass surface to keep moisture from condensing.

This technology is very effective, especially for freezers operating at sub-zero temperatures, where frost formation is common. However, since it requires electrical energy to maintain heating, it naturally leads to higher power consumption. Therefore, we mainly recommend heated glass for freezers, not for beverage coolers where energy efficiency is the priority.

When to choose:

- Best for freezers, low-temperature applications, or high humidity areas.

- Recommended when clear visibility is required even under frost conditions.

Choosing the Right Option

Each of these three solutions — Low-E glass, triple-layer glass, and heated glass — has its own unique advantages. At TCCOOL, we don’t believe there is one “universal” answer; rather, the right choice depends on your specific product design and environment.

If you are producing a beverage cooler for supermarkets or convenience stores, Low-E glass is usually the best solution because it keeps the door light, clear, and energy-saving. For freezers that must operate at much lower temperatures, heated glass is often the most reliable choice to prevent frost and ice build-up. In some tropical or coastal markets with consistently high humidity, triple-layer glass can be a perfect compromise between insulation and visibility.

In short, each type of anti-condensation glass has its role — and our engineering team will always recommend the most suitable configuration based on your target market and cabinet design.

Our Commitment to Clear Vision and Energy Efficiency

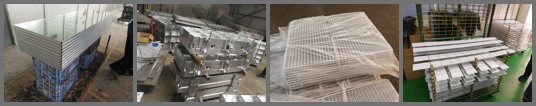

At TCCOOL Refrigeration, we focus not only on making products that cool efficiently but also on how they look and perform in real-world environments. Every showcase, cooler, and freezer we design aims to deliver both technical reliability and visual excellence. Whether you are an OEM partner, brand distributor, or supermarket chain, we can customize anti-condensation solutions that meet your product, budget, and regional climate needs.

We believe a clear glass door means a clear business opportunity — and that’s what we deliver every day.